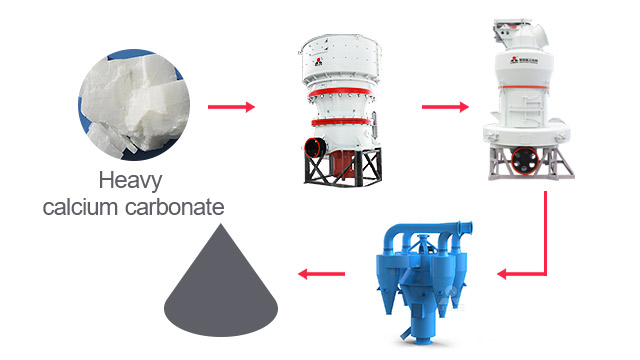

raw material

After grinding

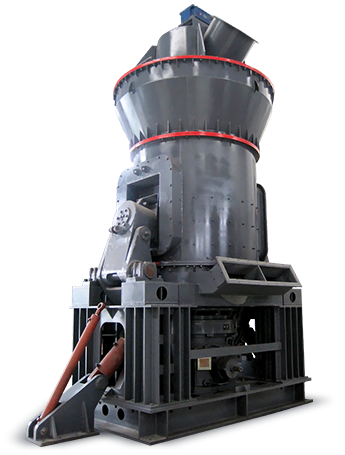

Heavy calcium carbonate mill

Heavy calcium carbonate is a commonly used powdery inorganic filler with high chemical purity, high inertia, not easy to occur chemical reaction, good thermal stability, no decomposition below 400 ° C, high whiteness, low oil absorption, low refractive index, soft and dry , Without crystal water, low hardness, low wear value, non-toxic, tasteless, odorless, good dispersibility and other advantages.

PROCESSING TECHNOLOGY

Heavy calcium carbonate (heavy calcium) is produced by directly crushing natural limestone, calcite, etc. by mechanical methods (milling equipment such as Raymond mill). Its production methods include dry milling and wet milling.

-

1The first stage: Crushing

Natural carbonate minerals such as calcite, marble, limestone and other large materials are crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill.

-

2The second stage: Milling

The crushed small pieces of material are sent to the silo by the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for grinding.

-

3The third stage: Grading

The powdered material is separated by the classifier, the unqualified powder will be returned to the grinding mill chamber for re-milling.

-

4The fourth stage: Collecting

Fine powder complies with the fineness and airflow go through the pipe into the dust collector for separation and collection. The finished powder will be transmitted to bucket elevator by screw conveyor and lifted into Silo for storage by Bucket elevator , then packed uniformly by powder tanker or automatic packing machine.