CM

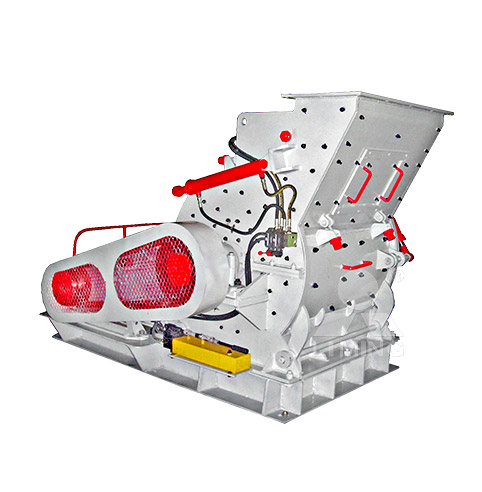

European Type Coarse Powder Mill

Processed Materials:

Limestone, calcite, dolomite, barite, talcum, calcium carbonate, gypsum, bentonite, etc.

Applications:

Calcium carbonate crushing processing, gypsum crushing processing, power plant desulfurization, non-metallic ore pulverizing, pulverized coal preparation.

Capacity:

8-70T/H

Capacity:

8-70T/H

Input size:

30-50mm

Input size:

30-50mm

Introduction

Hot Sale: Have performance advantages of grinding mill and crusher

Necessary equipment of medium and fine crushing work

Mainly suitable for crushing various soft and hard ores of compressive strength not higher than 320MPa (MPA).

High capacity, high crushing ratio, high rate of finished products

European Type Coarse Powder Mill is mainly suitable for crushing various soft and hard ores of compressive strength not higher than 320MPa (MPA), widely applied to metallurgy, mine, chemical industry, cement, coal gangue, construction, sand making, refractory and ceramics and so on.

Mill Gallery:

Product parameter

Technical Advantages

- 1High production capacity, high crushing ratio;

- 2Low power consumption, uniform product size;

- 3Simple mechanical structure, compact and portable;

- 4Low investment cost, convenient management.

Working Principle

CM Coarse Powder Mill is mainly composed of casing, rotor, impact iron and grid section. The motor and V-belt drives the main shaft, so as to make the rotor rotate. When the hammerhead is rotated, the centrifugal force will extend to all sides correspondingly. After large pieces of materials enter the crushing chamber from the feed port, they are squashed by the high-speed moving hammer. The qualified materials will be discharged from the lower part with a gap, and the unqualified materials will be left in the crushing chamber and repeatedly processed by hammer and hammer block until they can be discharged. In order to avoid blocking, the moisture content of crushed materials is generally less than 5%.