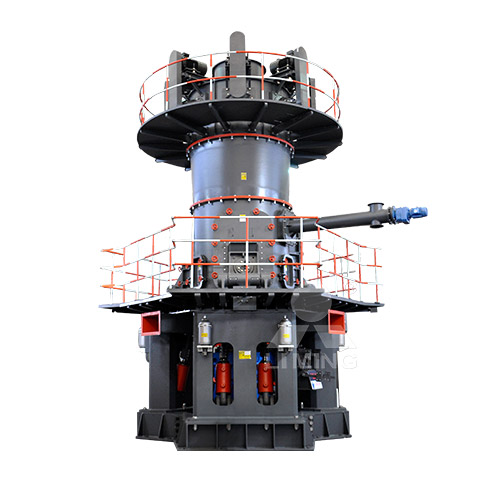

LUM

series superfine vertical roller grinding mill

Processed Materials:

Calcite, limestone, marble, dolomite, TSP, talc, barite and various materials under 7 moth hardness and less than 6% humidity.

Applications:

Chemical, building materials, coatings and other industries, superfine calcium carbonate, talc, dolomite, barite and other non-metallic mineral.

Capacity:

3-18T/H

Capacity:

3-18T/H

Input size:

10-20mm

Input size:

10-20mm

Introduction

Hot Sale: Integrate superfine grinding, grading and conveying together.Intelligent control, equipped with roller milling and rolling device, multi-head powder separator.Higher capacity, better powder quality, excellent comprehensive performances.

LUM series superfine vertical mil, integrating superfine grinding, grading and conveying together, is a professional and intelligent large-scale superfine milling equipment. It breaks through the bottleneck of ultrafine powder processing capacity, and its technical parameters, mechanical properties and quality of finished products can meet the clients' requirements for high-end products.

Mill Gallery:

Product parameter

Technical Advantages

- 1 Good finsished product quality: Adopting the principle of material layer grinding, The finished product has less repeated grinding, less iron content, high whiteness and clarity because material staying short time inside mill; Special designing grinding curve of the roller sleeve and liner can get 650 meshes at one time, even to 3250 mesh through secondary powder selection.

- 2 Stable equipment operation: Equipped with mechanical and electronic limit devices to avoid destructive impact and vibration; Adopt PLC/DCS automatic control roller grinding pressure control mode, the control is accurate, without manual operation; Equipped with grinding roller lubrication station, it can fully lubricate and prevent excessive oil leakage.

- 3 Reliable powder selection technology: Adopting the principle of multiple powder selection, all rotors can be adjusted by frequency conversion, which can effectively separate coarse powder and fine powder, and the separation fineness can be as high as 2μm; The equipment is energy-saving and the technology is reliable; the quality is stable and the reproducibility is high when producing many varieties.

- 4 Easy maintenance and environmental protection: The grinding roller does not directly contact with the mill stone, so it has less wear and long life; With hydraulic roller turning-out device, the grinding roller can be turned out of the machine completely to ensure enough maintenance space, which replace and repair easy-wear parts easily in a short time; Less vibration, lower noise, better overall sealing, no dust overflow;

Working Principle

LUM superfine vertical mill is mainly composed of motor, reducer, grinding roller device, grinding disc device, pressurizing device, powder separator, machine body and oil station.

The main motor drives the grinding disc to rotate through the reducer, and at the same time, the wind enters the mill from the air inlet, and the material falls on the center of the grinding disc through the discharge port of the screw feeder. In the area of the grinding roller table, the bulk material is crushed directly by the grinding roller, and the fine-grained material is squeezed to form a material bed for intergranular crushing. The pulverized materials continue to move to the edge of the grinding disc until they are taken away by the strong air flow at the wind ring, and the larger granular materials fall back to the grinding disc to continue grinding. When the materials in the air flow pass through the upper separator, Under the action of the blades, the coarse particles return to the grinding table for grinding, and the qualified fine powder is milled together with the airflow, and is collected by the powder collector of the system. The collected powder is the product of the ultra-fine vertical mill. When the iron pieces and other sundries mixed into the material move to the edge of the grinding disc, they cannot be blown up by the wind due to their own weight, and fall to the lower chamber of the mill and are scraped into the slag discharge port by the scraper installed at the bottom of the grinding disc to be discharged out of the machine.