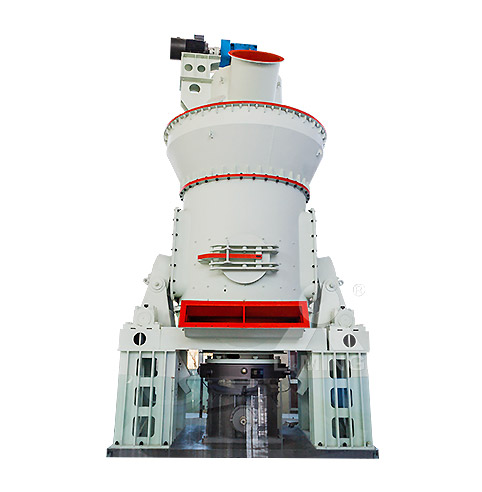

LM

Vertical slag mill

Processed Materials:

Cement, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag, etc.

Applications:

Cement, electric power, metallurgy, chemical, non-metallic ore and other industries.

Capacity:

7-100T/H

Capacity:

7-100T/H

Input size:

38-65mm

Input size:

38-65mm

Introduction

Hot Sale: Integrate drying, grinding, powder selection and conveying together

Adopt a unique grinding device to achieve the integration of grinding and powder selection, focus on slag milling.

The area is about 50% of the ball milling system. Energy consumption is 30% ~ 40% of the ball milling system.

As a new type of high performance concrete admixture, slag powder has the advantages of improving various properties such as compressive strength, tensile strength, shear strength and bending resistance of concrete. At present, the use of slag powder to replace the cement content in concrete and cement products, has become the main trend of building materials industry.

LM Vertical slag mill is a special equipment for grinding industrial waste into powder. Integrating drying, grinding, powder selection and conveying together, it is an ideal equipment for the slag powder production.

Mill Gallery:

Product parameter

Technical Advantages

-

1Why choose LM Vertical slag mill for grinding slag?

LM Vertical slag mill integrates drying, grinding, powder selection and conveying together, simple system, compact layout, the area is about 50% of the ball milling system. Reduce the cost of investment, low energy consumption, compared with the ball mill system, the energy consumption is 30% ~ 40%.

Working Principle

Drying the slag, then grinding the slag.