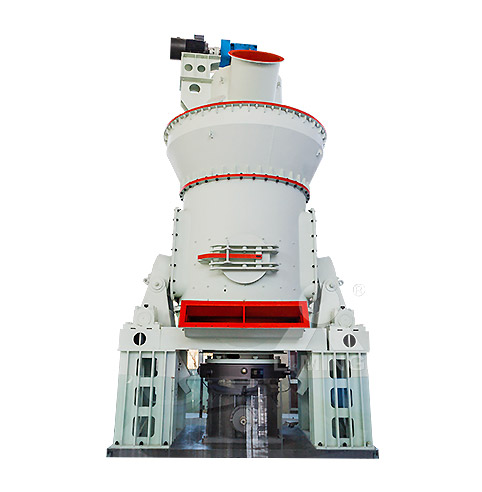

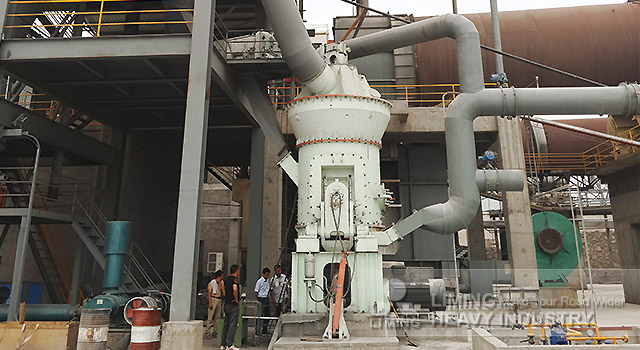

LM

Vertical Roller Mill

Processed Materials:

cement, coal, feldspar, calcite, talc iron ore, copper ore, phosphate rock, graphite, quartz, slag

Applications:

cement, electricity, metallurgy, chemical, non-metallic mineral ore and other industries

Capacity:

13-70T/H

Capacity:

13-70T/H

Input size:

38-65mm

Input size:

38-65mm

Introduction

Hot Sale: Integrates drying, grinding, powder selection and conveying together .

Liming Heavy Industry actively absorb successful abroad experience, and through the continuous technological innovation and upgrade of the R & D team, launched with independent intellectual property products: LM vertical mill. The equipment is widely used in cement, power, metallurgy, chemical industry and other industries.

Patent Certificate:

Mill Gallery:

Product parameter

Technical Advantages

- 1Low investment cost: It integrates drying, grinding, powder selection and conveying together, simple system, compact layout, the area is about 50% of the ball milling system.

- 2Easy operation and maintenance: It can realize remote control and easy to operate; convenient, reduce downtime losses

- 3Low operating cost.

- 4High efficiency: low energy consumption, compared with the ball mill system, the energy consumption is 30% ~ 40%; less wear and tear: long life, less wear and tear.

- 5Stable product quality.

- 6High drying efficiency: Strong drying ability, can save a dryer for the mill system, save energy; can meet the requirements of different humidity materials by adjusting the temperature of hot air.

- 7Environmental Protection: Small vibration, low noise, and the whole equipment is sealed, the system works under the negative pressure, no dust overflow, clean environment, meet the national environmental requirements.

Working Principle

Vertical Roller mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. The materials fall into the center of device through lock air feeder, and hot air comes into mill through air inlet under the function of centrifugal force, the materials when they come by the annular chute. The grinded materials will be taken up by air circulation and the bigger powder will fall down for regrinding. Qualified powders will be collected by collecting device as to be final product. Materials containing water will be dried when they contact with the hot air. Different humidify materials can be dried to the requirement through adjusting the temperature of hot air. Adjusting the separator can get the required fineness powders.