raw material

After grinding

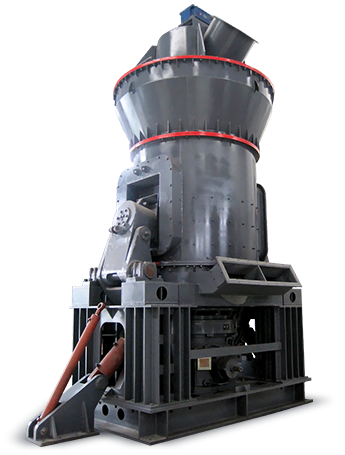

Limestone Grinding Mill

The main component of limestone is calcium carbonate (CaCO3). Lime and limestone are widely used as building materials and are also important raw materials for many industries. Limestone can be processed directly into stone and calcined into quicklime. Lime is divided into quicklime and slaked lime. After blending slaked lime becomes lime mortar, lime paste, etc.

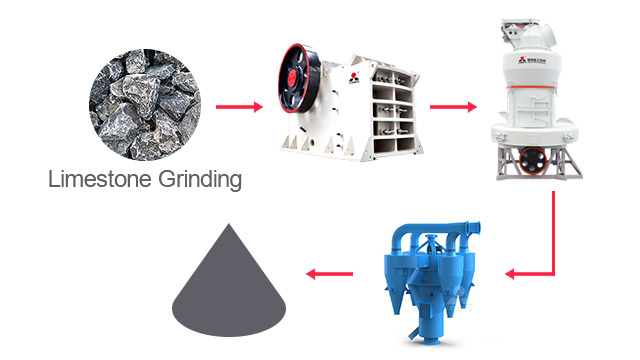

PROCESSING TECHNOLOGY

Limestone powder can be generally divided into coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), and ultrafine powder deep processing (400 mesh-1250 mesh) and micro powder processing (1250 mesh-3250).

-

1The first stage: Crushing

Limestone chunks are crushed by crusher to the input fineness of the mill (15mm-50mm).

-

2The second stage: Milling

The small pieces of crushed limestone are transported to the feed bin by the elevator, and then evenly and quantitatively transported by the vibrating feeder into the mill for grinding.

-

3The third stage: Grading

The material after grinding is classified by the classifier. The unqualified powder is sent back to the mill to be reground by the classifier.

-

4The fourth stage: Collecting

Fine powder complies with the fineness and airflow go through the pipe into the dust collector for separation and collection. The finished powder will be transmitted to bucket elevator by screw conveyor and lifted into Silo for storage by Bucket elevator , then packed uniformly by powder tanker or automatic packing machine.