raw material

After grinding

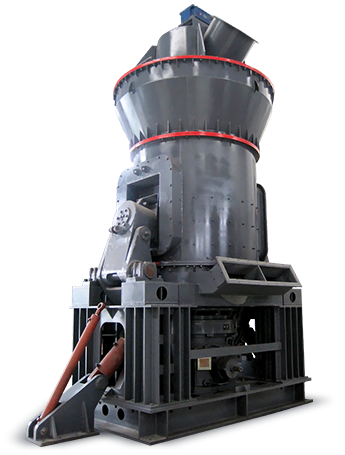

Bentonite Mill

Bentonite is a montmorillonite-based clay mineral, which can be divided into sodium-based bentonite and calcium-based bentonite. It can be used as binder, suspending agent, filler, catalyst, etc. It is widely used in petroleum extraction, directional crossing, steel casting, metallurgical pellets, chemical coatings field.

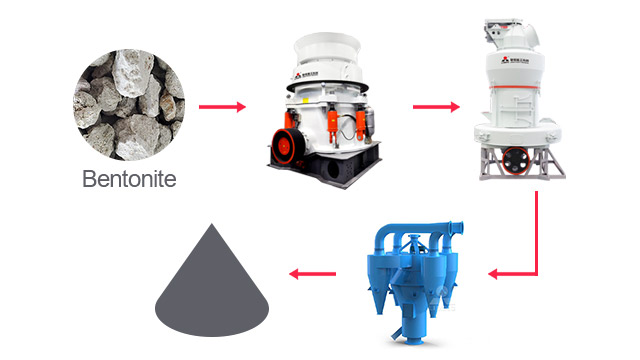

PROCESSING TECHNOLOGY

Bentonite powder can be generally divided into coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), and ultrafine powder deep processing (400 mesh-1250 mesh) and micro powder processing (1250 mesh-3250).

-

1The first stage: Crushing

The bulk bentonite is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill.

-

2The second stage: Milling

The crushed small pieces of bentonite are sent to the silo by the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for grinding.

-

3The third stage: Grading

The powdered material is separated by the classifier, the unqualified powder will be returned to the grinding mill chamber for re-milling.

-

4The fourth stage: Collecting

Fine powder complies with the fineness and airflow go through the pipe into the dust collector for separation and collection. The finished powder will be transmitted to bucket elevator by screw conveyor and lifted into Silo for storage by Bucket elevator , then packed uniformly by powder tanker or automatic packing machine.