raw material

After grinding

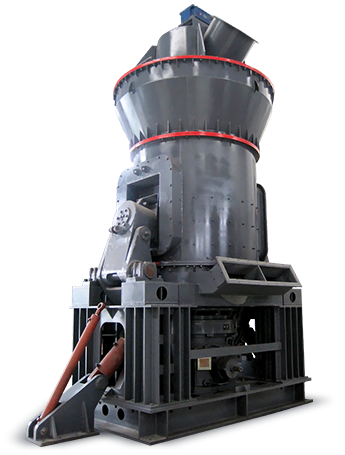

Coal mill

As a fossil fuel, coal is abundant in the earth and widely distributed. It can be summarized into two major uses according to the purpose of use: thermal coal and coking coal. For example, coal for power generation, steam locomotives, building materials, industrial boilers, metallurgy, and daily life is thermal coal; coking coal is mainly used for coking, and coke is mostly used for steelmaking.

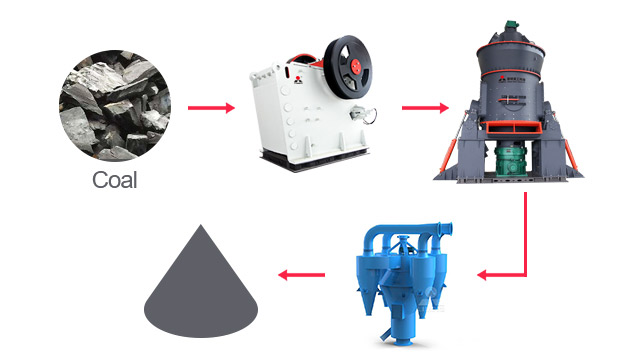

PROCESSING TECHNOLOGY

The blast furnace pulverized coal injection system has a very wide range of applications in the power, steel, and metallurgy industries. The quality of pulverized coal formed by the processing of raw coal determines the operating efficiency of the entire system. Preparation of pulverized coal need the following stages:

-

1The first stage: Crushing

Large pieces of coal are crushed by the crusher to the feed fineness of the mill ( 80% below 20mm)

-

2The second stage: Milling

The crushed small lump coal is sent to the silo by the hoist, and then sent to our grinding mill chamber for grinding evenly and quantitatively by the vibrating feeder.

-

3The third stage: Grading

The powdered material is separated by the classifier, the unqualified powder will be returned to the grinding mill chamber for re-milling.

-

4The fourth stage: Collecting

Fine powder complies with the fineness and airflow go through the pipe into the dust collector for separation and collection. The finished powder will be transmitted to bucket elevator by screw conveyor and lifted into Silo for storage by Bucket elevator , then packed uniformly by powder tanker or automatic packing machine.