Processed Materials:

Applications:

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Capacity:

0.65-50T/H

Capacity:

0.65-50T/H

Input size:

Up to 25mm

Input size:

Up to 25mm

Introduction

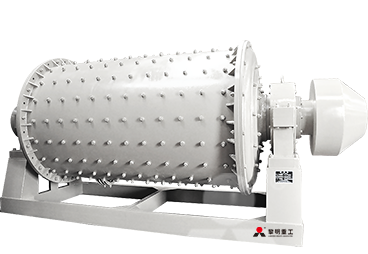

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed. It can grind all kinds of ores and other materials, which is widely used in beneficiation, construction and chemical industry.

Product parameter

Technical Advantages

- 1Wide application: It has many types, so it is can be used in lots of industries, such as powder making industry and mineral dressing industry.

- 2High crushing ratio: The crushing ratio can reach 300 and the finess is adjustable.

- 3Large capacity: Ball mill can meet large scale mineral dressing production line.

- 4Stable performance: Structure novelty, easy and safe to operate, stable and reliable performance, obviously reducing the downtime.

- 5Lower investment, energy saving.

Working Principle

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.