Integrated Pulverizing Process of Desulfurizer in Circulating Fluidized Bed Boiler (CFB)

Due to recent years, circulating fluidized bed boiler power plant emission standards have a new request, On the new high-sulfur coal unit desulfurization device put forward a very strict requirements, That is, about 100% of the desulfurization efficiency in order to meet the emission requirements. At present, to achieve this effect, simply in accordance with the way the furnace desulfurization of sulfur emissions of new standards, (CFB) desulfurization method is generally used in two types of combination of the way, that is, the furnace desulfurization and furnace flue gas desulfurization, the desulphurization of the new circulating fluidized bed power plant (CFB).

Whether it is the use of furnace desulfurization or the use of flue gas desulfurization furnace desulfurization methods, are required to grinding different grades of limestone powder. According to the characteristics of CFB boiler desulfurization, Liming Heavy Industry developed a new type of desulfurization and grinding equipment and technology.

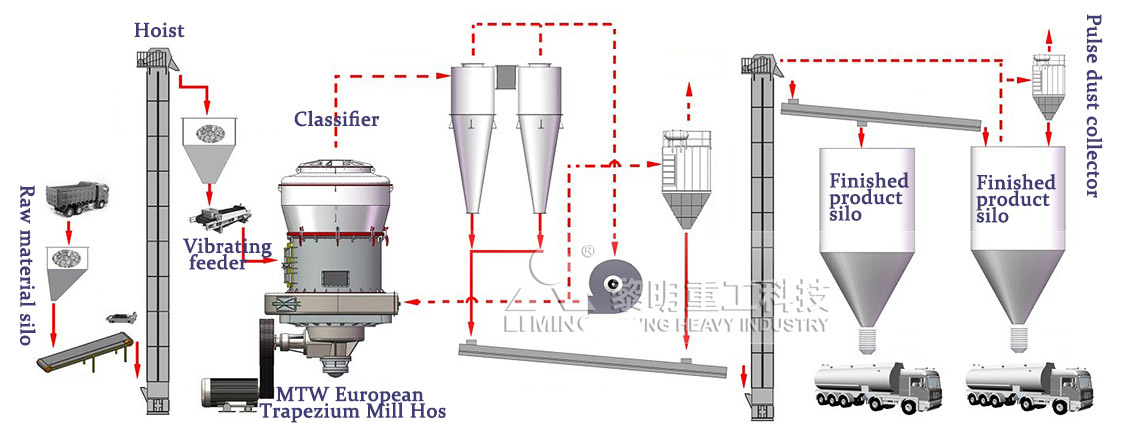

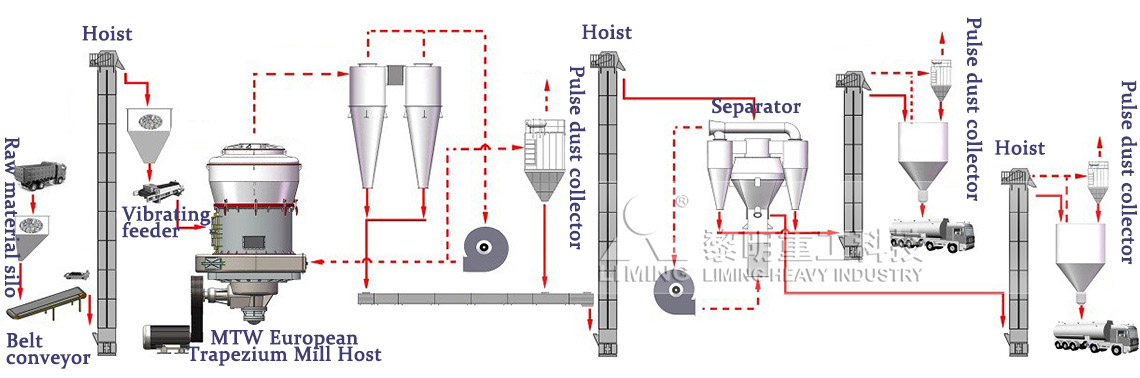

Furnace and out-of-furnace desulphurizer process flow

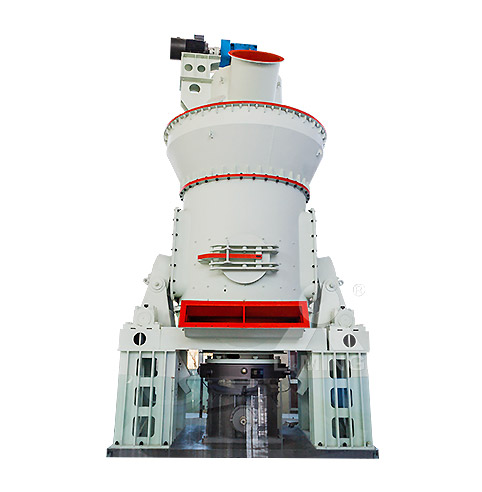

MTW European Trapezium Mill of Liming Heavy Industry using dry grinding, widely used in the furnace flue gas desulfurization powder making, Increase the secondary classification equipment, fully able to meet the powder demand for furnace and out-of-furnace at the same time, two different sizes of limestone desulfurization Powder, production of 1mm-0.045mm (furnace desulfurization) and 0-0.045mm (out-of-furnace desulfurization).

Flue gas desulfurization powder typical case